Umntu kufuneka aqale ngeenkcukacha ngokubanzi ukuze ahlole ukubaipali yesitalato yelangayimveliso efanelekileyo.

Iipali zesitalato zelanga zihlala zinciphile. Umatshini wokusika iipleyiti usetyenziselwa ukuzisika zibe ziipleyiti zetrapezoidal ngokobukhulu bazo obuhambelanayo, kwaye umatshini wokugoba usetyenziselwa ukuzisonga kwityhubhu enciphileyo. Xa uvavanya umgangatho wazo, khumbula la manqaku alandelayo:

1. Kuya kubakho ijoyinti kwityhubhu egobileyo emva kokuba ipleyiti yentsimbi igobile. Le joyinti kufuneka ivalwe kusetyenziswa umatshini wokuwelda we-arc ongaphantsi komhlaba. Le weld ibaluleke kakhulu. Ukuba iirola zomatshini wokuwelda we-arc ongaphantsi komhlaba azivumelaniswanga, iipleyiti zentsimbi kumacala omabini aziyi kulingana, nto leyo echaphazela inkangeleko. Jonga ijoyinti ukuze ubone imingxuma ye-pinholes. Ukuba kukho imingxuma ye-pinholes, nokuba emva kokufaka i-galvanizing kunye ne-powder coating, ukugqwala kwindawo ye-pinhole akuphepheki.

2. Ukuwelda kwi-flange kunye ne-power supply port kufuneka kube ngokulinganayo kwaye kube bushelelezi. Ekubeni yonke inkxaso ye-solar street pole ixhomekeke ezantsi, i-weld joint kufuneka ibe banzi kwaye ingabi nazikhewu. Ekubeni uninzi lwe-weld slag luhlala luchaphazwa ngexesha lokuwelda ngesandla, ukucoca ngononophelo kubalulekile ukuze kuthintelwe umonakalo omkhulu kubuhle.

Ngokwesiqhelo, kusetyenziswa izikrufu ezimbini ukubopha ingalo yeplanga yesitalato yelanga kwiplanga. Ukuqinisekisa ukuba umngxuma wocingo ucacile phakathi kwengalo neplanga kubalulekile. Abanye abavelisi beplanga lokukhanya basebenzisa ukusika ilangatye ukwenza umngxuma wocingo bezama ukonga ixesha nomgudu. Oku kubangela ukuba i-weld slag ijikeleze udonga lwangaphakathi lomngxuma, nto leyo eyenza ukufakwa kwindawo kube nzima kwaye kuthathe ixesha.

3. Jonga i-galvanization ye-solar street pole. Ubukhulu beleyali ye-galvanization kufuneka bufane. Ubukhulu obungalinganiyo kwi-pole enye, nangona ingeyongxaki inkulu, bubonisa isiphene kwinkqubo ye-galvanization. Kwakhona, jonga i-gloss. I-galvanization elungileyo iya kuba nokukhanya kwesilivere phantsi kwelanga; umphezulu ongenanto, okhanyayo ubonisa imveliso engaphantsi komgangatho eya kugqwala ngokukhawuleza.

4. Ukufakwa komgubo we-powder yinyathelo lokugqibela ekuvelisweni kwe-solar street pole egqityiweyo. Amandla ayo okumelana nomhlwa alandela ukugaya, kodwa akwabalulekile. Inkqubo entle yokufakwa komgubo we-powder ibukeka igudile kwaye ifana, ngaphandle kwamabala alahlekileyo, kwaye xa ujonga ngokusondeleyo, akukho zimpawu zokutshintsha umbala. Ukuvavanya ukunamathela kokufakwa komgubo we-powder kwi-pole, ungasebenzisa incam yentsimbi ebukhali ukukrwela ngokunyanzeliswa umgca kwindawo engabalulekanga, njengaphantsi kwe-flange. Jonga ukuba nayiphi na i-powder coating iyaphakamisa na kumacala omabini okukrwela. Ukuba akunjalo, ukunamathela kuyamkeleka. Ukuba kukho ukuphakanyiswa, kubonisa ingxaki ngenkqubo yokufakwa komgubo we-powder. Oku kunokukhokelela ekuqhekekeni okukhulu kokufakwa komgubo we-powder ngexesha lokuthuthwa, okuchaphazela ukubonakala kwaye kunciphisa kakhulu ubomi bokumelana nomhlwa.

La manqaku angasentla awanakushwankathela ngokupheleleyo yonke inkqubo, kodwa ukuba onke la manqaku ayanelisa, ngoko i-solar street pole ingathathwa njengemveliso efanelekileyo.

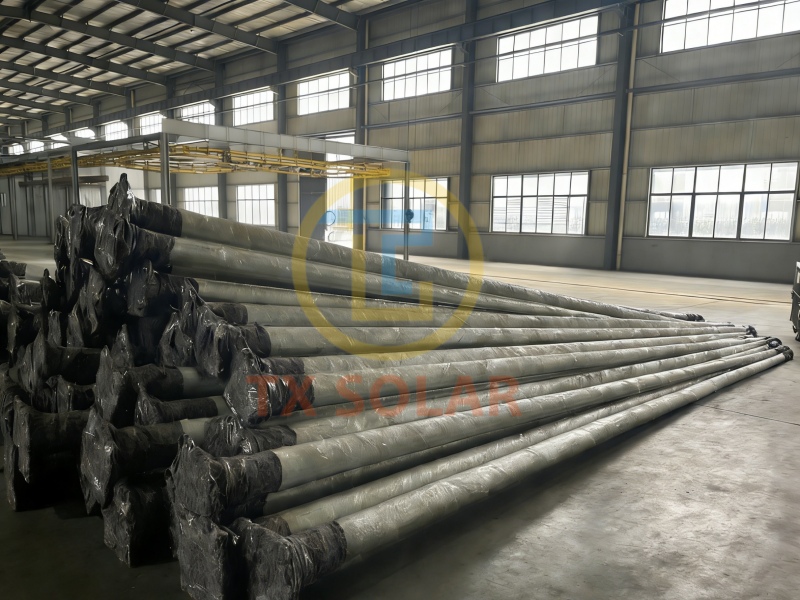

Ifektri yezibane zasesitalatweni saseTianxiangIbithumela iipali zezibane zasezitalatweni kwamanye amazwe kangangeminyaka engamashumi amabini, kwaye ziyathandwa kakhulu ngabathengi bamazwe ngamazwe. Iimveliso zethu zixhasa ubude kunye nobubanzi obulungiselelwe wena, kwaye kulula ukuzifaka. Sinikezela ngamaxabiso akhuphisanayo kunye nokuhanjiswa okuzinzileyo, ngezaphulelo zeeodolo ezinkulu. Simema ngokunyanisekileyo abakhi beenkampani zobunjineli kunye nabasasazi ukuba basebenzisane nathi!

Ixesha leposi: Disemba-23-2025