Iipali zokukhanya ezigayiweyoziyinxalenye ebalulekileyo yeziseko zophuhliso zasezidolophini, zibonelela ngokukhanya ezitalatweni, kwiipaki nakwiindawo zikawonke-wonke. Njengomthengisi ophambili weepali zokukhanyisa ezikhanyisiweyo, iTianxiang izibophelele ekuboneleleni ngeemveliso ezisemgangathweni ophezulu ezihlangabezana neemfuno ezahlukeneyo zabathengi. Kweli nqaku, siza kuhlola inkqubo yokwenziwa kweepali zokukhanyisa ezikhanyisiweyo, sigqamise ukubaluleka kokufaka iipali zokukhanyisa kunye neenzuzo ezizisayo.

Ukuqonda i-Galvanizing

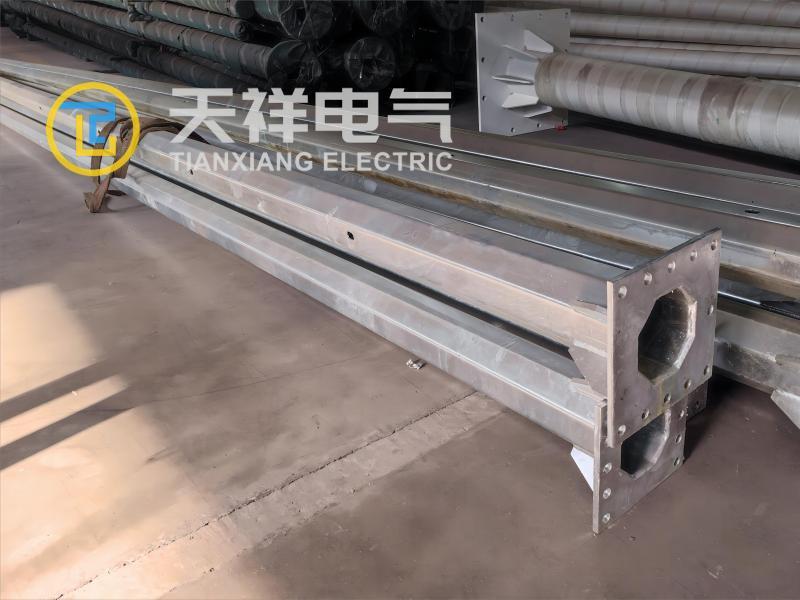

Ukugaya intsimbi yinkqubo egquma intsimbi okanye isinyithi ngomaleko we-zinc ukuthintela ukugqwala. Olu gquma lukhuselayo lubalulekile kwiipali zokukhanya, ezihlala zichatshazelwa yimozulu embi, kuquka imvula, ikhephu, kunye nobushushu obugqithisileyo. Inkqubo yokugaya intsimbi ayipheleli nje ekwandiseni ubomi beepali zokukhanya, kodwa ikwanciphisa neendleko zokulungisa, nto leyo eyenza ukuba kube lukhetho olufikelelekayo koomasipala kunye namashishini.

Inkqubo yokuvelisa ipali yokukhanya ekhanyisiweyo

Ukuveliswa kweepali zokukhanya ezigqunyiweyo kubandakanya amanyathelo aliqela abalulekileyo, ngalinye lichaphazela ukuqina nokusebenza kwemveliso yokugqibela. Nantsi inkcazo eneenkcukacha zendlela ezenziwa ngayo iipali zokukhanya ezigqunyiweyo:

1. Ukukhetha izinto

Inyathelo lokuqala ekwenzeni iipali zokukhanya ze-galvanized kukukhetha izinto ezifanelekileyo. Intsimbi esemgangathweni ophezulu idla ngokusetyenziswa ngenxa yokuqina kwayo nokuqina kwayo. Intsimbi ifunyanwa ngababoneleli abathembekileyo ukuqinisekisa ukuthotyelwa kwemigangatho yoshishino. KwaTianxiang, sibeka phambili umgangatho wezinto eziluhlaza ukuqinisekisa ukuba iipali zethu zokukhanya ze-galvanized zihlala ixesha elide.

2. Ukusika nokubumba

Nje ukuba intsimbi ikhethiwe, iyasikwa ibe nobude obufunekayo kunye nemilo. Le nkqubo inokubandakanya ukusetyenziswa koomatshini abaphambili ukuqinisekisa ukuchaneka kunye nokuhambelana. Iipali zokukhanya zinokuyilwa ngobude obahlukeneyo kunye nobubanzi, kuxhomekeke kwindlela ezisetyenziselwa ngayo. Umzekelo, ipali yokukhanya yesitalato inokuba nde kunepali yokukhanya esetyenziswa epakini okanye kwindawo yokuhlala.

3. Ukuwelda kunye nokudibanisa

Emva kokusikwa, izinto zentsimbi ziyadityaniswa ukuze zenze ulwakhiwo lwepali yokukhanya. Eli nyathelo libaluleke kakhulu kuba liqinisekisa ukuba ipali yokukhanya iqinile kwaye inokumelana noxinzelelo lokusingqongileyo. Abawelda abanobuchule baseTianxiang basebenzisa ubuchwepheshe obuphambili ukwenza amalungu aqinileyo aphucula ukuthembeka kwepali yokukhanya iyonke.

4. Ukulungiswa komphezulu

Ngaphambi kokuba kusetyenziswe i-galvanizing, iipali zombane zilungiswa ukuze kususwe naluphi na ungcoliseko olufana nomhlwa, ioyile okanye ukungcola. Eli nyathelo libalulekile ukuqinisekisa ukuba i-zinc coating inamathela ngokufanelekileyo kwintsimbi. Inkqubo yokulungisa umphezulu idla ngokubandakanya ukucoca iipali ngeendlela ezifana nokuqhumisa uthuli okanye ukucoca ngeekhemikhali.

5. Ukugaya ngentsimbi

Eyona nto iphambili kwinkqubo yokwenziwa kwemveliso kukugalela i-galvanizing. Iipali ezilungisiweyo zintywiliselwa kwibhafu ye-zinc enyibilikisiweyo kubushushu obumalunga nama-450 degrees Celsius. Le nkqubo ibangela ukuba i-zinc isabelane nentsimbi ekwintsimbi, yenze uthotho lweeleya ze-zinc-iron alloy ezibonelela ngokumelana nokugqwala okugqwesileyo. Iipali emva koko zisuswa ebhafini zize zipholiswe, nto leyo ephumela kwingubo ekhuselayo eqinileyo.

6. Ulawulo lomgangatho

Apha eTianxiang, sithatha ulawulo lomgangatho nzulu kakhulu. Emva kokufaka i-galvanizing, ipali nganye ihlolwa ngokungqongqo ukuqinisekisa ukuba iyahlangabezana nemigangatho yethu ephezulu. Oku kuquka ukujonga ubukhulu be-zinc coating, ukuhlola ii-welds, kunye nokuqinisekisa ukuba ipali ayinaziphene. Ukuzinikela kwethu kumgangatho kuqinisekisa ukuba iipali zethu ze-galvanizing zithembekile kwaye zihlala ixesha elide.

7. Izinto zokugqiba

Nje ukuba iipali zidlule kulawulo lomgangatho, zinokuthi zigqitywe ngakumbi njengokupeyinta okanye ukongeza izinto zokuhombisa. Nangona iipeyinti ze-galvanized zibonelela ngokhuseleko oluhle kakhulu, abanye abathengi banokukhetha umbala othile okanye ukugqitywa ukuze kuhambelane neemfuno zabo zobuhle. KwaTianxiang, sinikezela ngeendlela ezenzelwe wena ukuhlangabezana neemfuno zabathengi bethu ezizodwa.

8. Ukupakishwa kunye nokuhanjiswa

Okokugqibela, iipali zokukhanyisa ezigqityiweyo ze-galvanized zipakishwa ngononophelo ukuze zihanjiswe. Siqinisekisa ukuba zipakishwe ngokukhuselekileyo ukuthintela umonakalo ngexesha lokuthuthwa. Njengomthengisi weepali zokukhanyisa ze-galvanized othembekileyo, uTianxiang uzimisele ukuhanjiswa ngexesha elifanelekileyo, eqinisekisa ukuba abathengi bethu bafumana ii-odolo zabo xa bezifuna.

Iingenelo zeepali zokukhanya ezigalelwe nge-galvanized

Iipali zokukhanya ezifakwe i-galvanized zibonelela ngeenzuzo ezininzi ezenza ukuba zibe lukhetho oluthandwayo kwiintlobo ngeentlobo zezicelo:

Ayikwazi Ukugqwala: Ingubo ye-zinc ikhusela intsimbi kumhlwa kunye nokugqwala, yandisa ubomi bepali.

Ulondolozo Oluphantsi: Iipali zegalaji azidingi ulondolozo oluphezulu, nto leyo enciphisa iindleko zexesha elide koomasipala nakumashishini.

Ukuqina: Ulwakhiwo oluqinileyo lweepali zokukhanya ezenziwe nge-galvanized luqinisekisa ukuba ziyakwazi ukumelana neemeko zemozulu ezinzima kunye nokusetyenziswa rhoqo.

Ubuhle Bokubukeka: Iipali zokukhanya ezifakwe i-galvanized zineendlela ezahlukeneyo zokwenza ngokwezifiso ukuphucula ubuhle bendawo kawonke-wonke.

Ukuququmbela

Ngamafutshane,inkqubo yokuvelisa iipali zokukhanya ze-galvanizedIbandakanya amanyathelo aliqela abalulekileyo, ukusuka ekukhetheni izinto ukuya ekutsaleni i-galvanizing kunye nolawulo lomgangatho. Njengomthengisi ophambili weepali zokukhanyisa ezikhanyisiweyo, iTianxiang iyaziqhenya ngokubonelela ngeemveliso ezikumgangatho ophezulu ezihlangabezana neemfuno zabathengi. Ukuba ufuna iipali zokukhanyisa ezikhanyisiweyo ezihlala ixesha elide nezithembekileyo, siyakumema ukuba unxibelelane nathi ukuze ufumane ikowuteshini. Iqela lethu likulungele ukukunceda ekufumaneni isisombululo esifanelekileyo kwiimfuno zakho zokukhanyisa.

Ixesha leposi: Disemba-26-2024